Designing a wireless charging pad

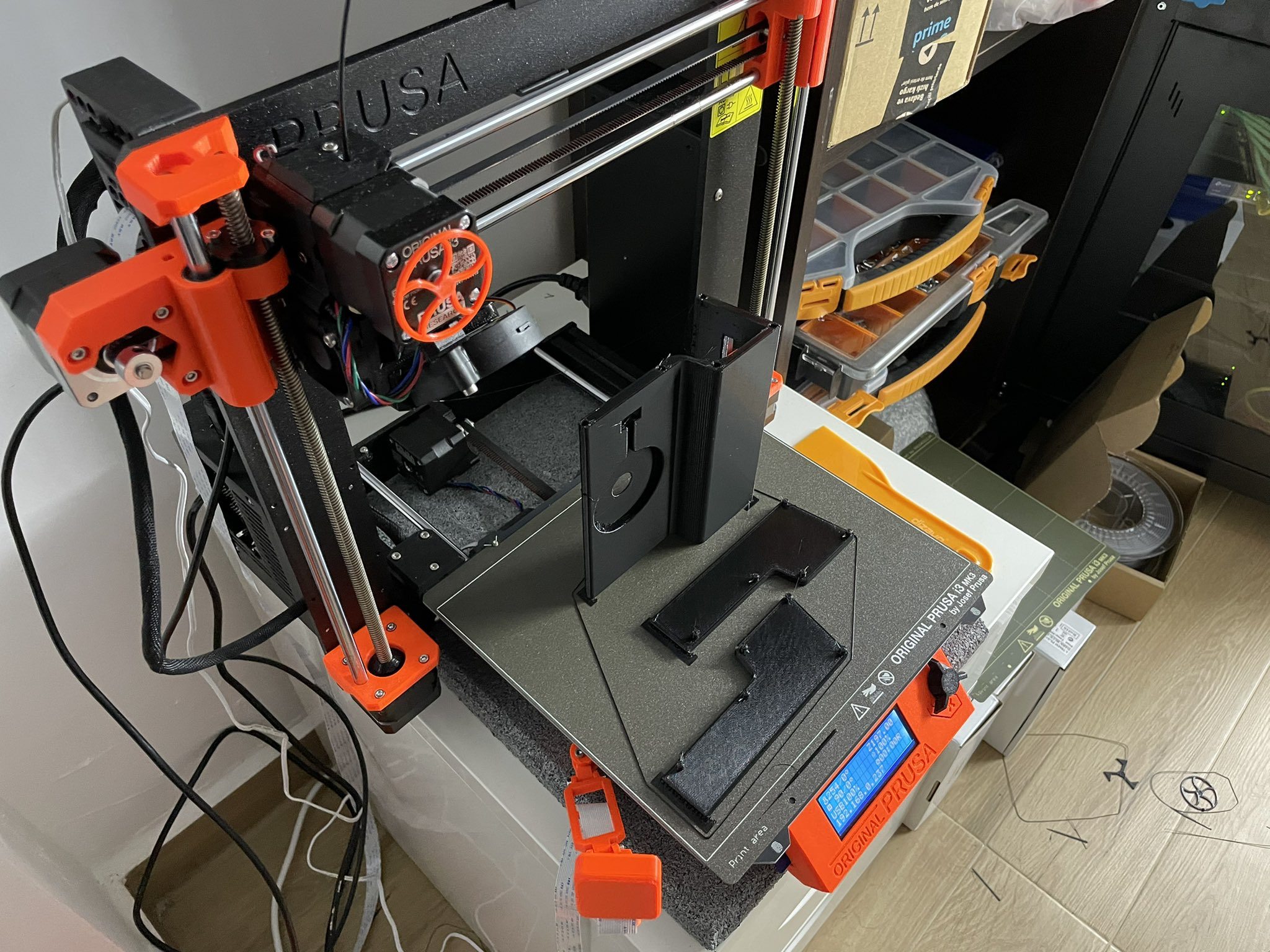

In my previous blog post, I talked about how I got into 3D printing and upgraded my 3D printer with a webcam and remote access. Since then, I've been using it for many 3D prints that I downloaded from Printables.com or Thingiverse.com.

However, I mainly purchased a 3D printer to print my designs, and I also had to learn CAD software to create a custom design. But first, what could I design? Or rather, what could I design to solve a problem of mine?

After 3 months of waiting, my new car was delivered. And as with all vehicles, a few things were missing due to the chip shortage. One of them is a Wireless Charger station. Most cars have a dedicated storage section where you can put your phone for wireless charging. And because most new vehicles also have Wireless CarPlay, it's really convenient.

Luckily, the center console (the only place I could put a phone) had 2 USB-C ports. So, that's something we're going to use.

So, I decided to design and 3D print a custom "MagSafe Charger" station tailored for my car's center console. I'm using an iPhone 12 Pro, which supports MagSafe Charger. I could, of course, start using the USB-C port from day one with my MagSafe Charger. But it wasn't user-friendly, it was a hassle to put the phone down and grab it again, and the center console was a total mess due to the cable intermingle.

Tools and gear I used

For prototyping, I used the following devices and tools:

- Apple iPad Pro 12.9-inch Pro: For general research, CAD, sketching, everything that comes to mind. I just love this device.

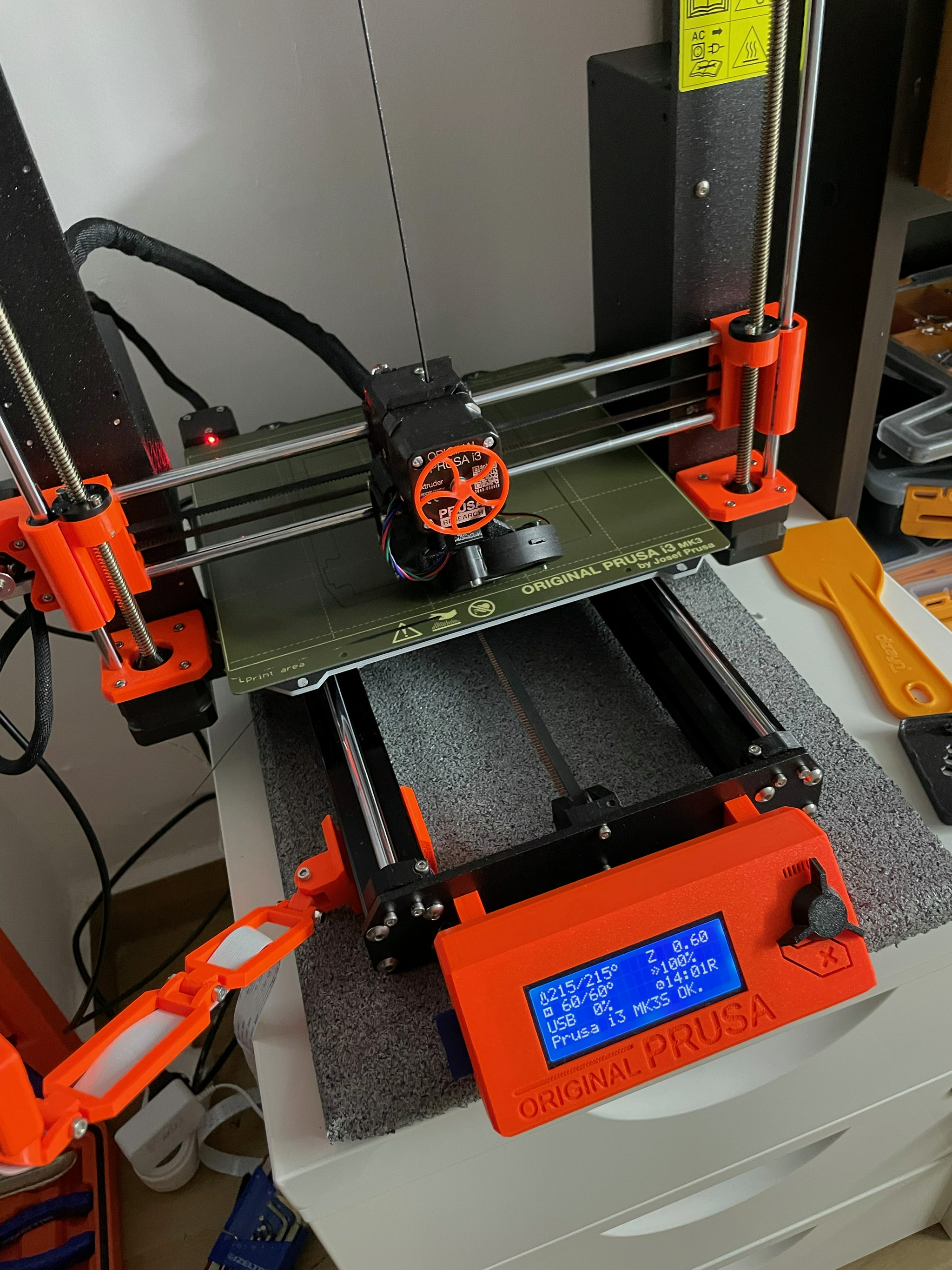

- Prusa i3 MK3S+ 3D Printer: If you have read my previous blog post, I'll explain more about my 3D printer.

- Mitutoyo Digital Caliper: To design a 3D model, we need to know precisely every measurement in all three axes. I've used the caliper to measure the center console dimensions, cable widths, MagSafe accessory details, and many other minor things.

- Plier: To take out the supports from my 3D model. 3D models sometimes have "supports". These are additionally printed to support overhanging details (because a 3D printer can't print in the air). Once a print is finished, we have to remove the supports manually.

I only used the following software:

- Shapr3D: a CAD software specially made for the iPad. All my designs in this blog post are created using Shapr3D.

- Prusa Slicer: The official Slicer software for turning my 3D models into G-Code files, so the 3D printer knows how to print a 3D model.

- Apple Notes: for quick sketches, notes, and gathering/collecting information (such as Apple's official MagSafe accessories PDF)

Let's start!

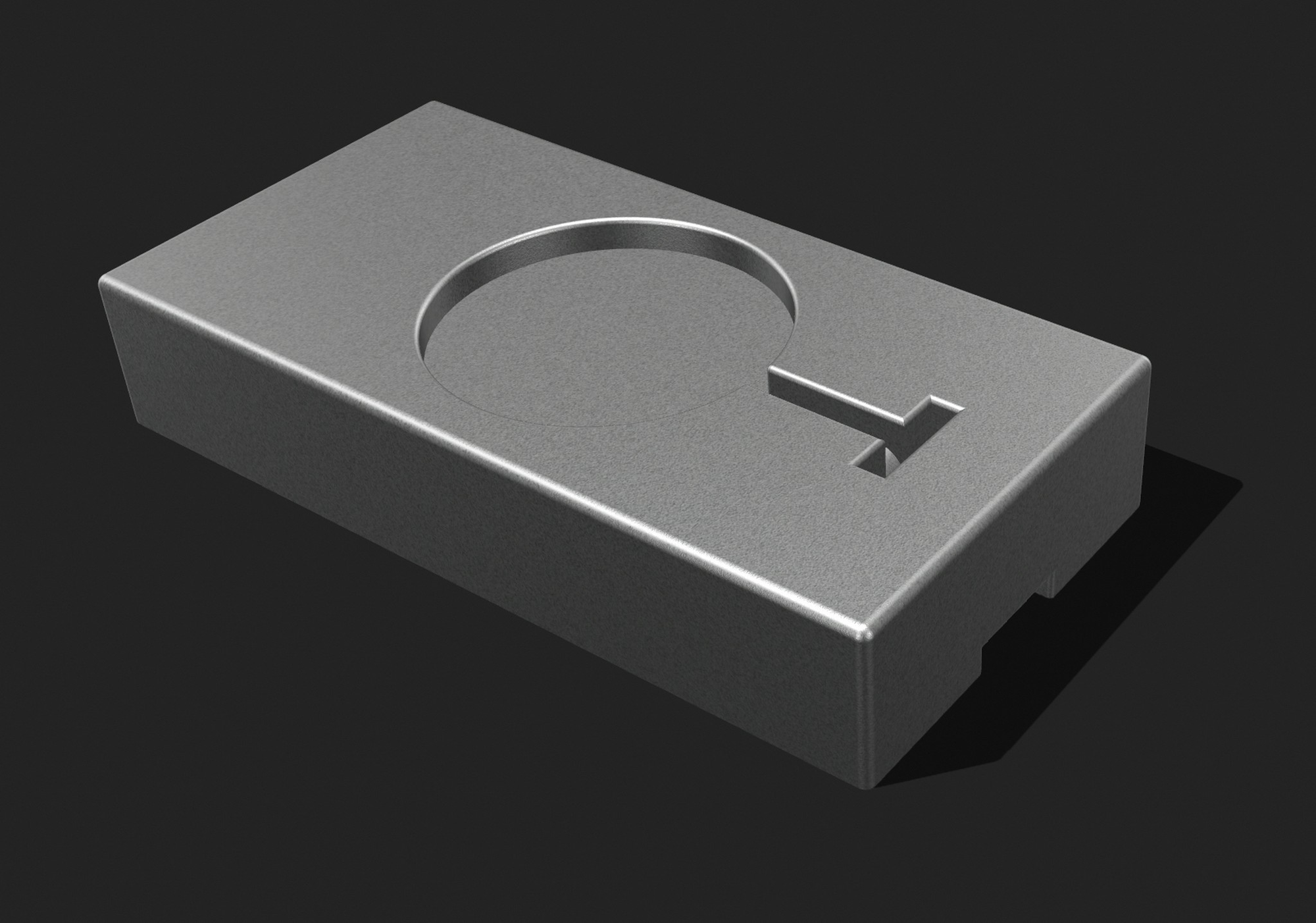

First iteration - The block

The first iteration was pretty basic. A diagonal block with a place to insert a MagSafe Charger pad. It wasn't pretty, but I thought I wouldn't need such a thing. After printing, it tried to put it inside the center console.

As you see, the length wasn't a 100% perfect fit. And also, I was using Shapr3D's free offering; hence my design was exported in a low resolution, leading to certain inefficiencies, such as the circle being not a perfect circle. However, that wasn't the main issue here, and the problem was that I had the wrong measurements for the cable insert.

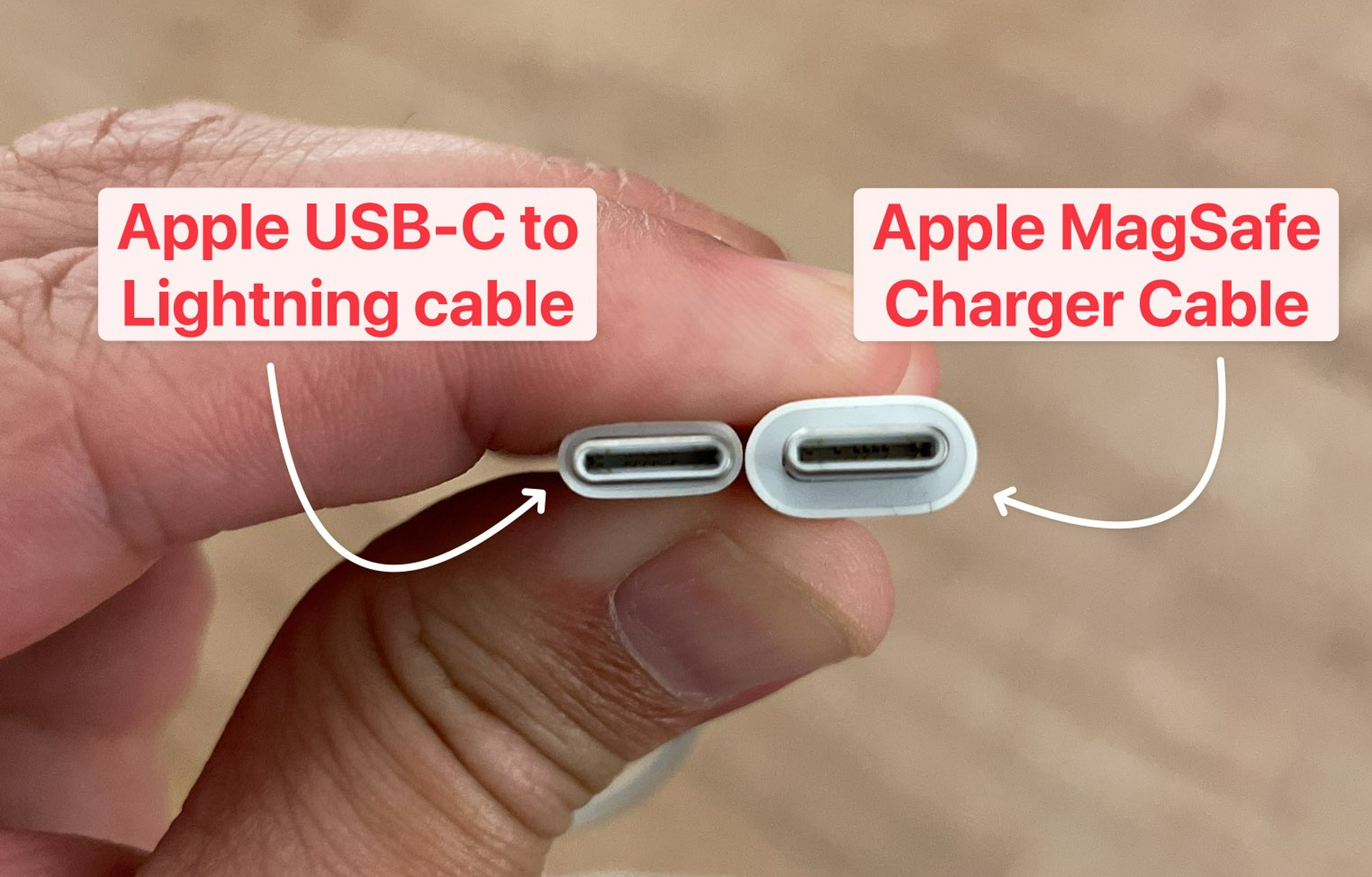

I took a USB-C Apple cable from the drawer and measured the female port section. However, I discovered that the MagSafe Charger's plug was thicker than a standard Apple USB-C cable plug. Not the actual USB-C plug, but the thick housing surrounding the connector. In fact, a lot of USB-C cables have a different connector widths and thicknesses.

There were other issues with this first initial design:

- Placing the phone on the charger and grabbing it would rip off the whole charge station because of the strong magnets. I had to hold with one hand the charge station and grab it with another.

- Because the charge station wasn't a perfect fit when I would stop the car, the model would rattle around.

- The cable would stick out, occasionally preventing placing the phone.

- It was ugly.

Second iteration – Back to the drawing board

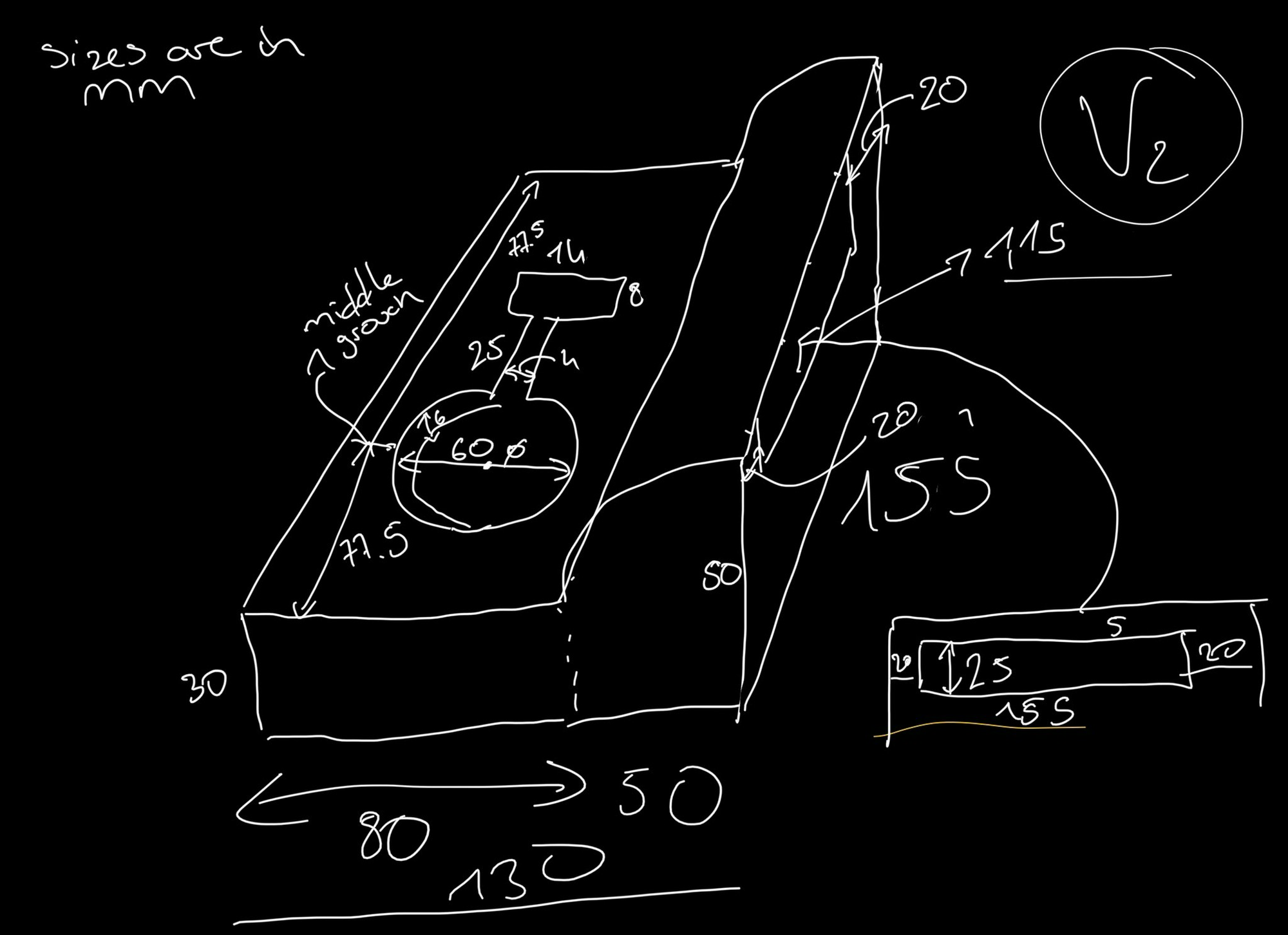

I sat down, took my iPad, opened Apple Notes and Shapr3D, and started designing a better iteration. The v2 iteration looks similar to the final iteration, so I believe I nailed it. First, before 3D modeling it via Shapr3D, I thoroughly measured every part of the center console with my caliper. I sketched the rough idea first.

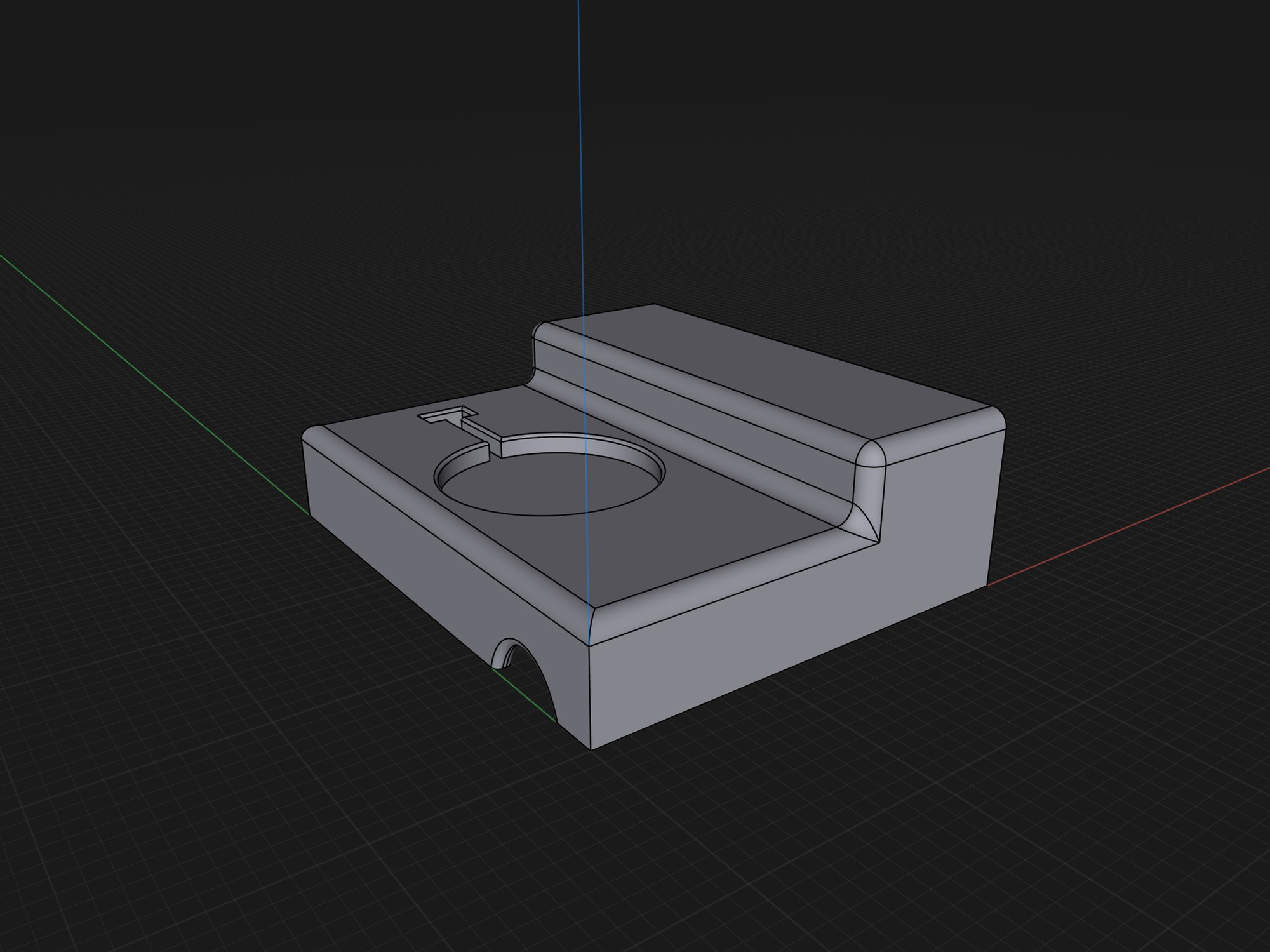

After the sketch, I started designing it on Shapr3D. I have to say, the more I used Shapr3D, the more I liked it. I like devices (like my iPad) where I can grab and work whenever I have spare time. It's the same reason I use my Nintendo Switch more often than my Xbox. Anyway.

What did I change in this design?

- I change the orientation. It's now fitting the center console vertically, hence perfectly fitting.

- The center console USB-C ports are not visible anymore; hence placing the phone doesn't interfere with anything anymore.

- There is a small cutout on the front to allow a second USB-C cable to be used for charging.

- I fixed the cable hole for the MagSafe's USB-C charger cable.

- It's better looking than my first iteration.

As you see in the photo, this looked much better than the previous. I could easily stop here and call it a day. However, there were a couple of slightly annoying things. First, of the good parts, I was happy because I could quickly put and grab my phone. However, it wasn't a %100 fit. It was slightly loose, not a lot anymore, but still, I could feel it.

Third iteration – Improvements

I sat down again and started modifying my existing design. I came up with a new design that would incorporate several further improvements:

- A slight edge to stop sliding the phone. Even though the MagSafe magnets are strong, I added a small lip at the border to prevent the phone from wobbling.

- 5 mm wider. This change makes sure that it fits the center console perfectly. Even if I hard-break the car, it doesn't wobble anymore.

- 5 mm longer at the back via a 15 deg slope. This is hard to tell, but the center console is not a square box, and the end of the center console has a slight incline. If you look carefully, you could see the ports in the previous iterations, but you don't see them anymore with this design.

- Cable holder extension to be used with a Zip tie. Even though we don't see the cable anymore, the wires were not tied anywhere. I could now connect the cable with a zip tie with the little wing.

- A hole for the MagSafe insert to take it out easily. After working on so many iterations, taking out the MagSafe from the charge station was a hassle. Furthermore, to ensure I can replace it in the future, I put a small hole underneath the MagSafe pad. That way, I can push it from the bottom, and it comes off easily.

- PETG instead of PLA. The previous iterations were printed with the PLA material; however, it's not the best choice for car accessories because cars can get very hot during the summer (especially where I live). PLA deforms easily in warm environments. PETG, on the other hand, is better suited because it's more tolerant of higher temperatures. (For those who are curious, there is an informative YouTube video where someone experiments with various materials inside a car)

After using this third iteration for a while, I've found some annoying things and inefficiencies in the design. However, printing the 3D models over and over became time-consuming, and printing a single model was around 17-18 hours.

How could I speed up the process?

Fourth iteration – Modular Design

First, what improvements were needed:

- The charging station would perfectly fit; however, because the center console is not that deep, I also lost quite a bit of space. I could use the area underneath the MagSafe charger, which was a hollow space.

- The small lip I added wasn't helpful; it prevented me from placing and taking out the phone quickly. I wanted to remove it.

- Because the phone would cover the charging pad area, I had to grab it from all sides to take it out. I could make my life much easier if one side was shorter and empty underneath the phone. That way, I could grab the phone directly from the side.

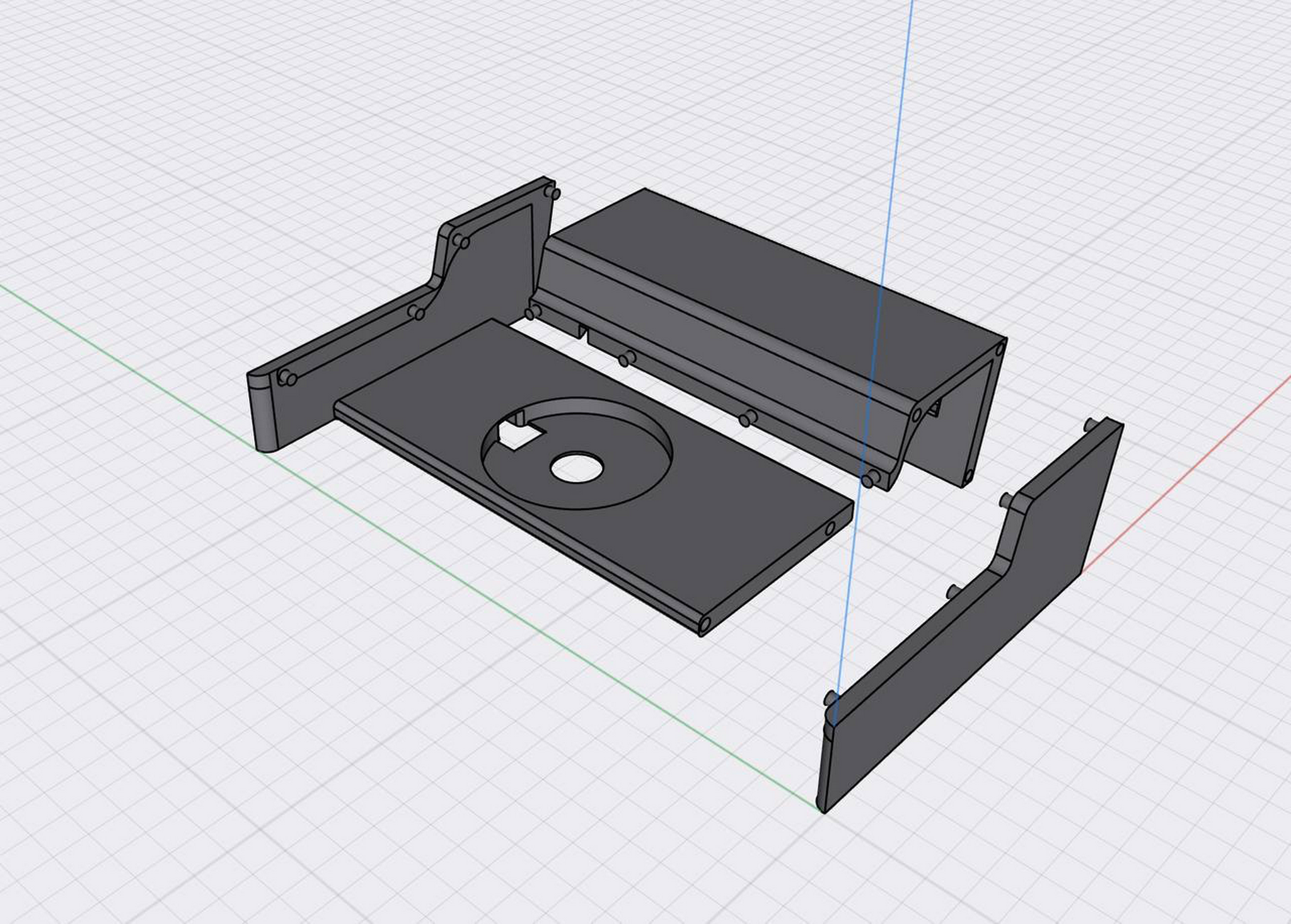

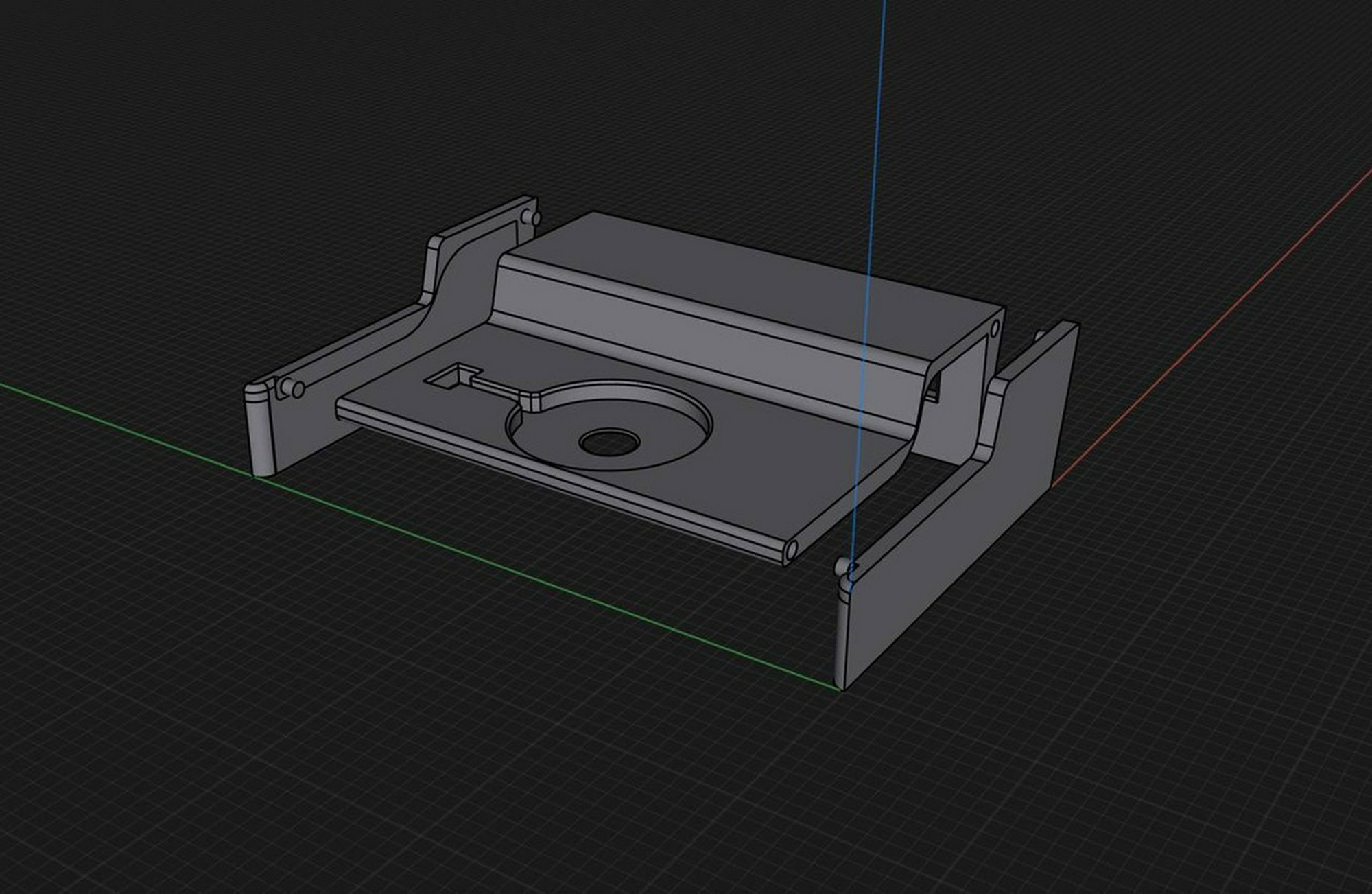

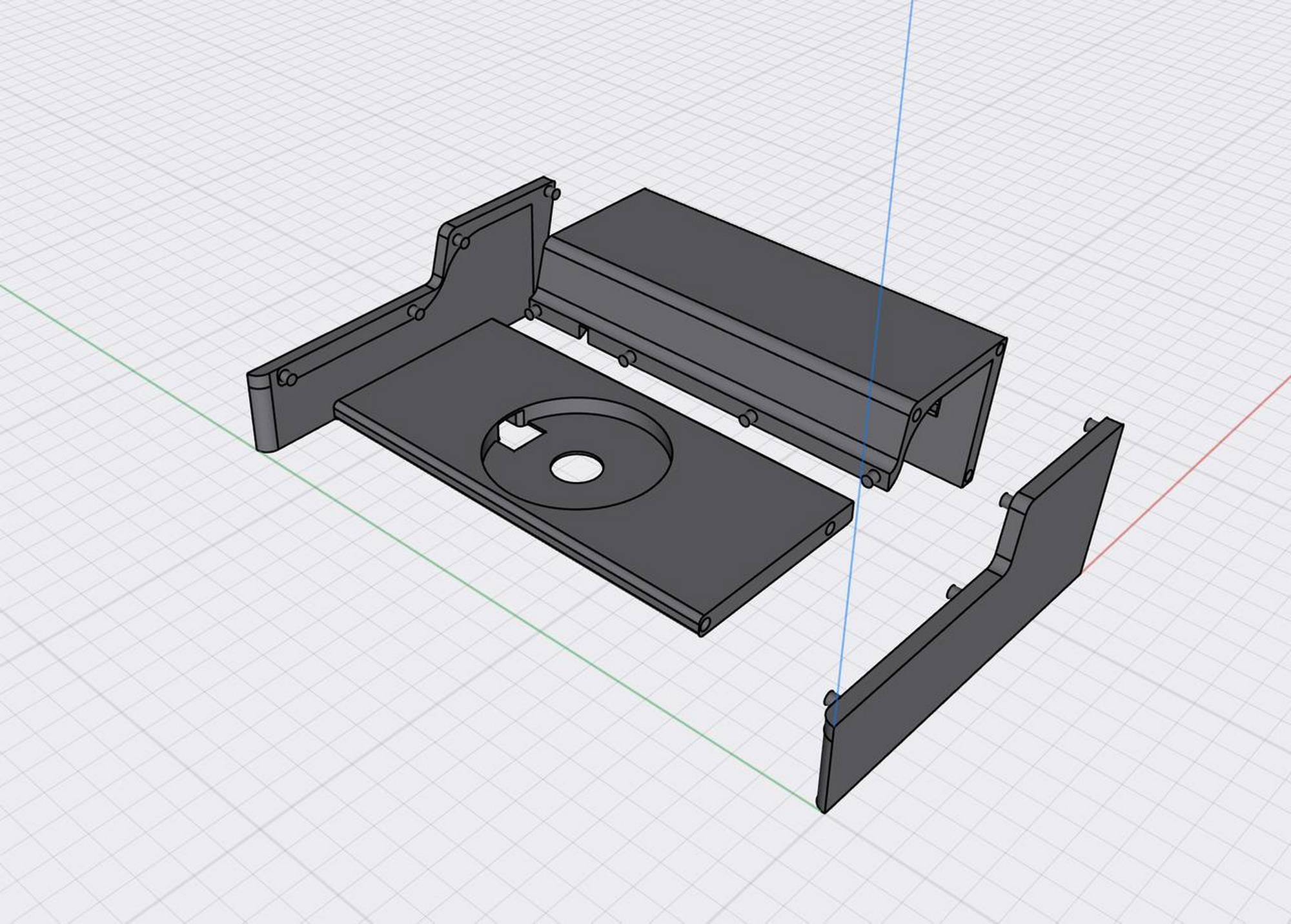

I decided to make it modular because it would take a lot of time to print the model. At least while I am still prototyping the final design.

The modular design would consist of three pieces. Two sides and one middle piece. That way, I could print each part without support. Without supports means that all the time spent printing the supports is no longer needed.

Making the design modular improved the print time from 18 to 10 hours, and it was a game-changer. I could now iterate on the design and spend half the time printing the pieces.

As you see in the photo, this iteration would allow me to put small items underneath the charging station, such as napkins, pens, etc.

Fifth iteration – Hiding the cable canal

When I posted my fourth iteration on Twitter, some of my followers shared a couple of 3D models of MagSafe chargers where the cable canal was hidden from the surface and was tucked underneath the charging station, so it wasn't visible. I dug into this as it was yet another improvement towards a better-looking design.

Because of the modular design approach, I could only work on the middle section and print the center section.

After working on hiding the cable canal, I split the centerpiece into two parts. Now the whole model would consist of four pieces.

As you see from the photos, the newer version looks cleaner and more straightforward.

Was this the final version, though?

Sixth iteration – Wrapping with fabric

Now that I've used it for prototyping, the modular version was beneficial in many ways. However, creating a modular version isn't easy, as you must ensure the holes and stubs fit perfectly. The accuracy of the stubs is tricky because of 3D printing's current limitations. To keep it short, it wasn't as stable as the one solid piece models.

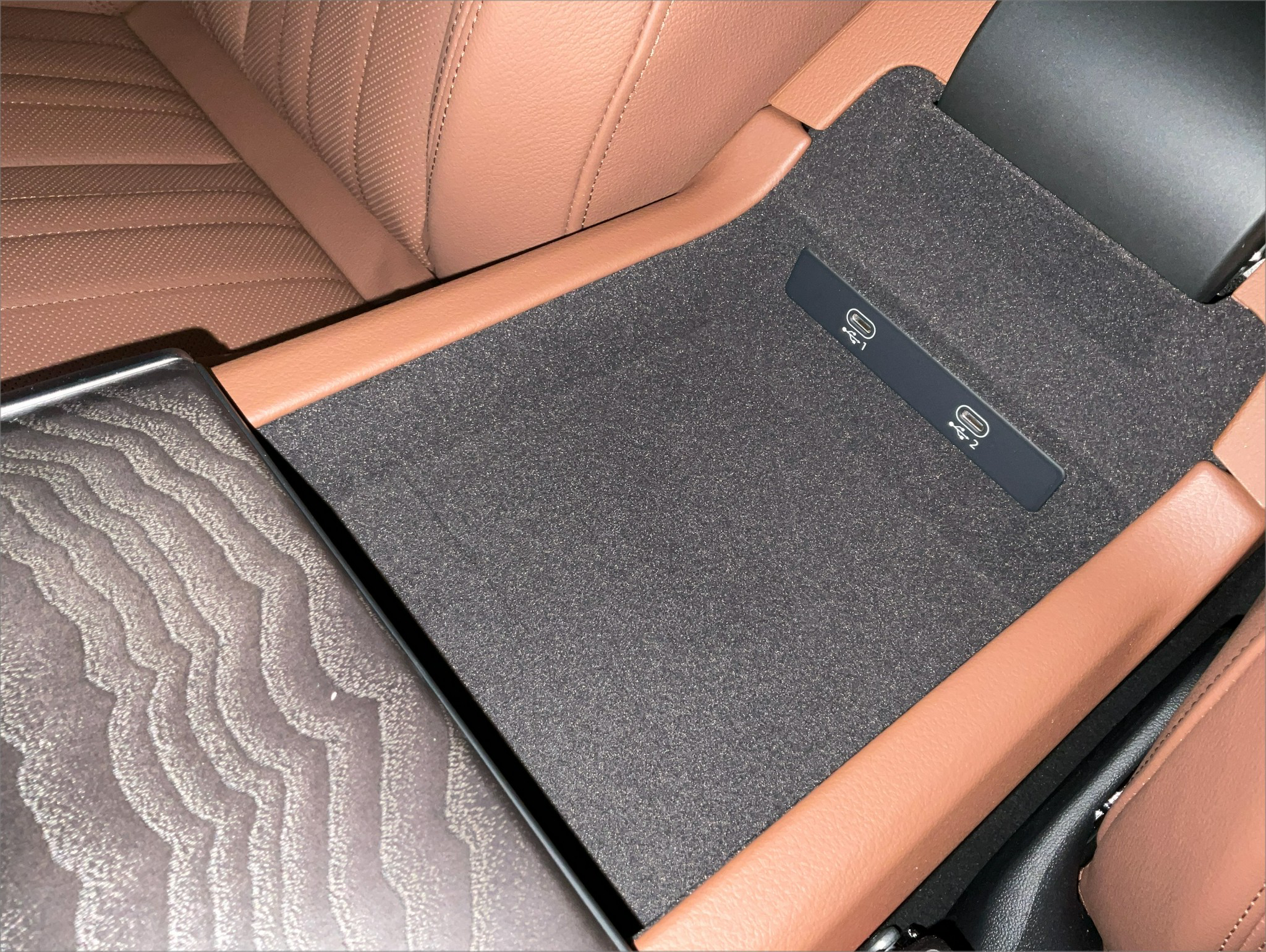

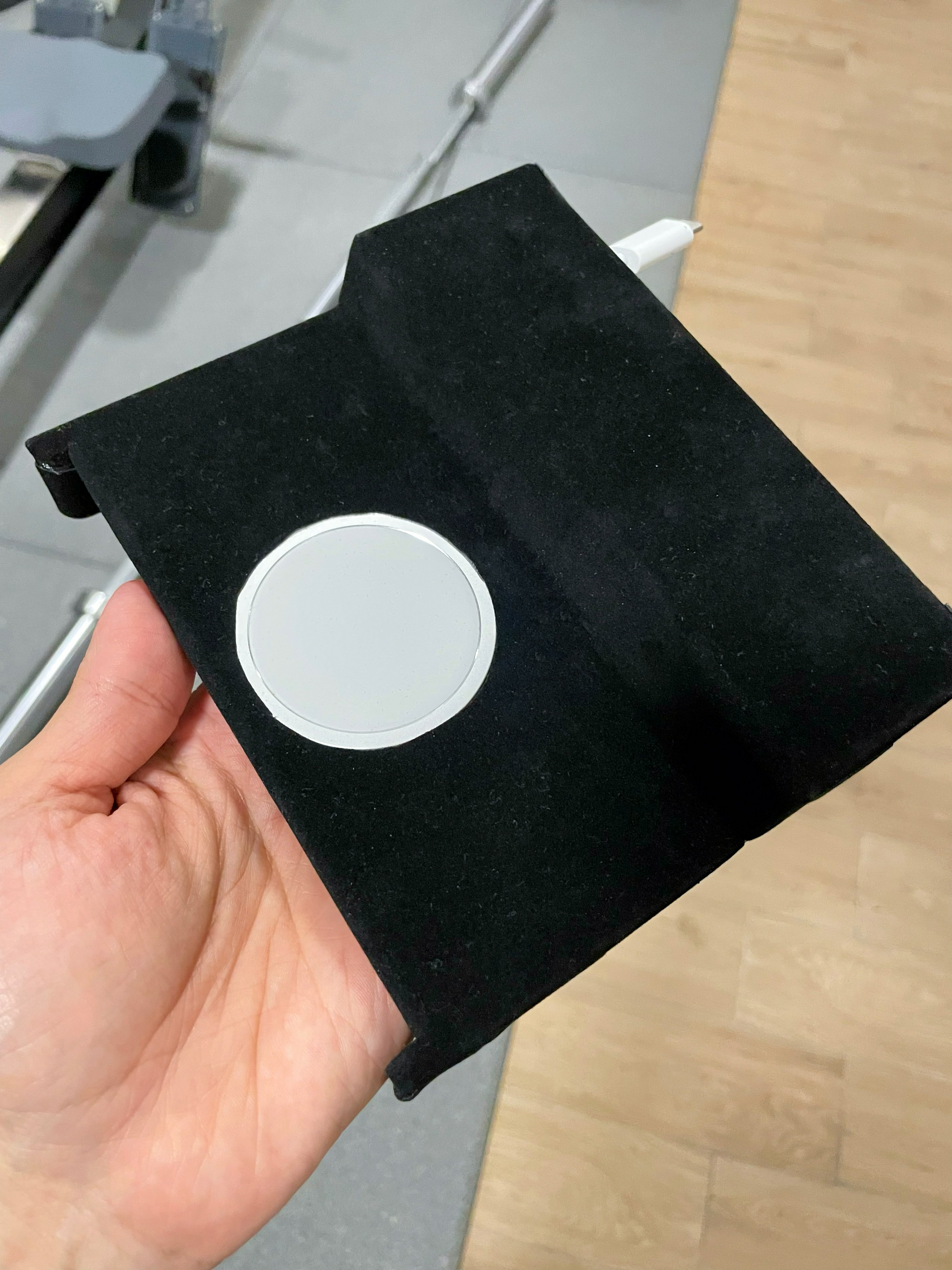

Now that the design was final, I decided to print it as a single block. While doing it, I also reminded myself that I wanted to wrap it with a fabric to match the interior materials of the car's center console.

I didn't know what to use, but I somehow stumbled across a seller that would sell fabrics in various colors with a self-adhesive side. That was perfect! It would mean I could just attach the material to my 3D model.

Cutting a perfect circle wasn't easy, but several hours later, I could finally cut a piece of fabric with a hole big enough to accommodate the MagSafe pad.

Here are the photos of the final design, where the whole model is wrapped with fabrics.

Verdict

After numerous iterations, I finally finished the project. Here is a photo of all iterations next to each other:

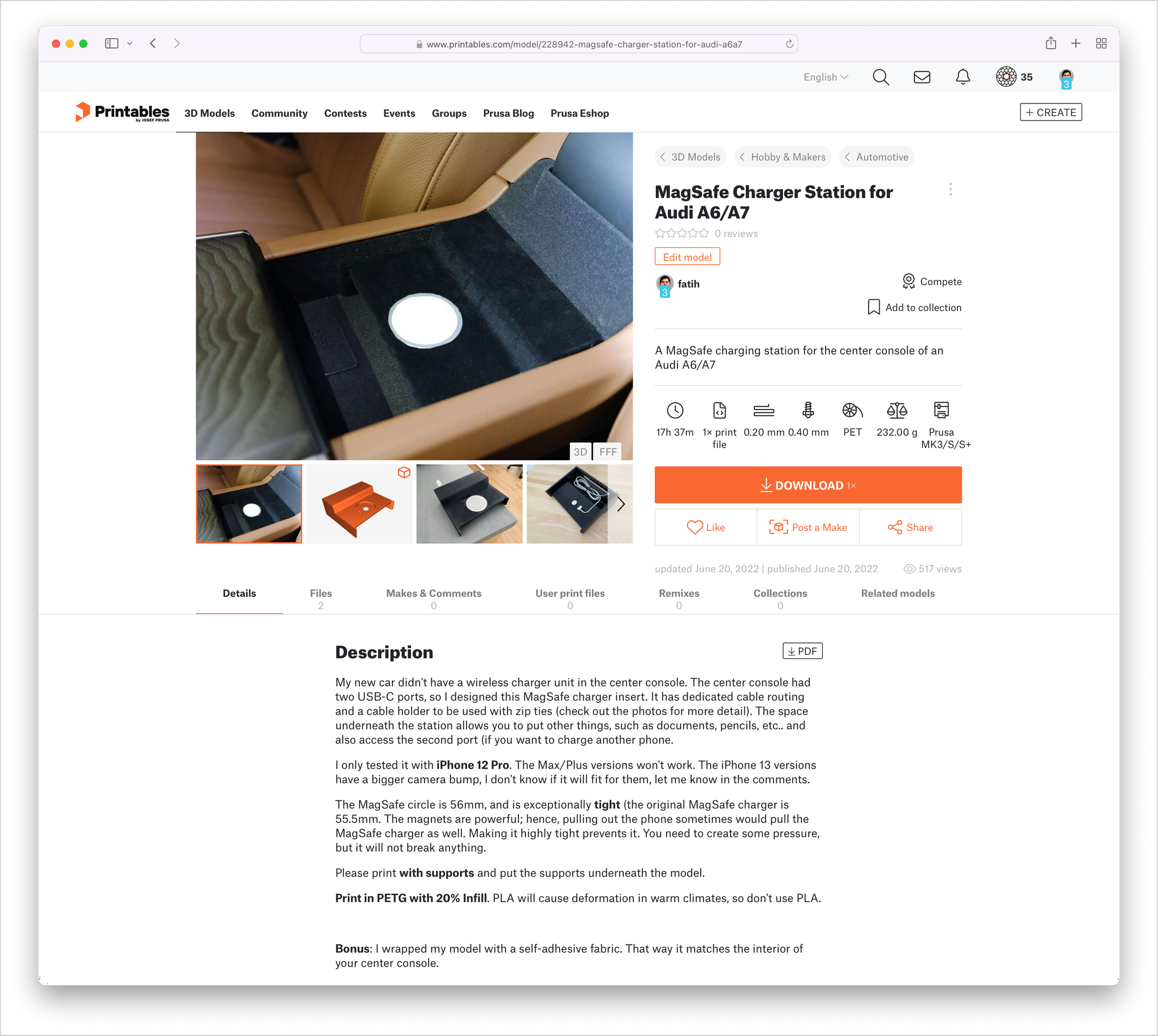

To ensure I give back to the 3D community, I also decided to share my STL files on Printables.com. If you have an Audi A6/A7 or any Audi car with a similar center console, you can print this design and start using it immediately.

What I liked the most about the process was how someone could get into industrial design with an iPad and a 3D printer. Once you know where to look and have an idea, it's easy to kickstart the whole prototyping process.

If you have read this so far, thank you! You can imagine how great it feels to iterate on a real-world object. I'm pleased about the outcome and using my 3D printer to solve real issues I encountered was just phenomenal.